- ACCIONA

- Press room

- Blog

- 2020

- July

- The digital twin, anot...

The digital twin, another step forward in ACCIONA’s commitment to technology

21/07/2020By Julio de la Rosa, ACCIONA ME Business Development Director for our water solutions

While the concept of a digital twin has been around since 2002, it is only thanks to Building Information Modeling and the Internet of Things (IoT) that it has become cost-effective to implement. A digital twin is a full virtual model of a process, product or service. This pairing of the virtual and physical worlds allows analysis of data and monitoring of systems to head off problems before they even occur, prevent downtime, develop new opportunities and even plan for the future by using simulations.

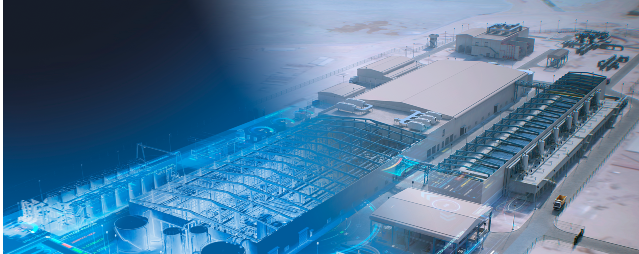

We have leverage all the innovation processes done by ACCIONA and have implemented a digital twin in our seawater reverse osmosis desalination plant in Al-Khobar 1, located in Dhahran, Saudi Arabia, which will have a capacity of almost 210,000 m³ per day, making it one of the largest desalination plants in the country, serving a population of 350,000 inhabitants. Among the different advantages of getting its exact digital reproduction are the remote management of the plant to analyze and optimize productivity and avoid failures before start-up by providing a comprehensive support for commissioning activities.

The development of a digital twin now a day has two main elements:

- One related to the engineering design with regard to BIM systems, which work directly to create objects that provide valuable information and a collaborative platform for the entire project.

- The other one is the digital twin related to the control system based on the most advance sensors and instrumentation able to capture in real time all the functionalities of the system to be able to check a plant’s response at any given time, as for example the real response of a control system that has been developed in back office. It combines a variety of technologies such as virtual reality, augmented reality, the Internet of Things or Machine Learning.

Creating the digital twin of Al-Khobar 1 has been a complex operation that requires the integration of different disciplines with a know-how about the process, mechanical equipment, electrical equipment, instrumentation, control system and simulation platform.

Thanks to our joint work with Siemens, we have been able to use SIMIT software, which allows real-time simulations ranging from devices in the field to processes in a water treatment plant.

This creates a collaborative environment in which carrying out a virtual start-up and having a training station for operators can be done in a safe and secure manner.

It also allows the comparison of the data created in the digital twin with those contained in the control system. This facilitates the validation of operations, as well as the exploration of operational possibilities in the system and potential optimization measures.

The digital twin is been integrated into ACCIONA’s Water Control Centre (CECOA) with the same standards of cybersecurity and communications channel availability as those applied in connections with other plants. This means that access to all functionalities is made in a fast and flexible manner.

This is a real need in the water sector, because we need to be more productive, faster, more efficient and be sure that our systems will arrive to the plants with the maximum efficiency and availability in order to be started up in the shortest possible timescale.

Digital systems integration

When we talk about digitization, the time horizon changes and that's why we must abstract a little bit of what can come thanks to the speed of change of technology.

I believe that Artificial Intelligence has a lot of field within desalination. Processes can be supported by systems that convert operating year’s data into value information to generate optimizations and intelligent models. All variants of Machine Learning, Deep Learning and uses of neural networks and big data will generate improvements that will interact with the control systems which, maybe, they will be systems to help the operation decisions.

Another technology that has a lot of field is the IIoT (Industrial Internet of Things), a variant of IoT. It will generate a plant-level information ecosystem that will affect the processes in various ways:

- One for its ability to generate value information from the data, becoming the process measures into information.

- Larger systems at the cloud level will be born from its connectivity capacity, which will improve, often online the capabilities of the device itself. We will see an impact on both the operation and the maintenance of the installation itself.

I would also add here other technologies that are already present in many projects. BIM technologies used in the designs, using digital twins to analyze, check the control system and draw conclusions in the design phase, and of course connectivity technologies with the relevant technical aspects of cybersecurity as a premise. I also leave 5G here as a technology that can be disruptive in this and many sectors, but we have to wait a little to face it in closed systems such as industrial desalination-type production facilities.

Another technology that is landing is the use of vocal assistants. I see scope to interact in certain cases with our plants using natural language and speech management and recognition systems. It's not that it's a plant requirement, but that I see an evolution of how humans are interacting with the systems around us.

On the technologies that will arrive, I believe that in desalination there will be a lot of journey in the use of technologies such as nanotechnology and biotechnology on processes, (pretreatments, filtration systems, Reverse osmosis, after treatments, use of chemicals...).

I also see indications of the use of robots or intelligent autonomous systems. Perhaps repetitive, check-up or inspection tasks can be developed by Robots designed for industrial environments and systems with hazardous areas.

Keeping all this in mind, we cannot forget that people is who can implement and hinder a process of digitization in desalination and in all industrial sectors. The main obstacle to saving is the fear of change.

In fact, we need to beat the fear of connectivity with technology and good practices. Now, in many of the new projects and many of those in operation, cybersecurity and its management are priority at all levels.

View ACCIONA Social Networks