- ACCIONA

- Press room

- Blog

- 2020

- May

- Disassembling the myth...

Disassembling the myths of the Waste to Energy Plants

15/05/2020By David de Lara, ACCIONA ME Country Manager for our Industrial Business

Waste-to-energy (W2E) plants are increasingly under focus across the Middle East, as governments recognize that this technology can solve two problems with one solution: First, to generate energy out of non-recyclable waste and then help the UAE strategy to achieve its goal to divert 75% of its solid waste from landfill sites.

Before the appearance of the Covid-19, rapid economic development in the region has improved the quality of life for people across the Gulf, but the down side is that it is accompanied by a heavy increase in the amount of municipal solid waste: The Arabian Gulf urban residents produce nearly twice as much amount of waste that their counterparts in Western Europe. When we look at the waste produced in urban environments around the world, especially in Western and European cities, the average is around 1.2 kg of waste per person per day while in the Middle East region we are closer to 2 kg per person per day.

In this scenario, W2E offers a great opportunity as a suitable solution for the two goals explained above. The UAE has already pioneered the possibilities that lay within W2E plants.

In Sharjah, Bee’ah in cooperation with Masdar, are developing a very large incineration W2E plant. On completion, the plant will divert more than 300,000 tons of solid waste from landfill each year, while producing 240,000 MW-hours of clean energy.

Another good example is the Al Warsan WTE, where Dubai Municipality and DEWA are cooperating in the development of the AED 2.5 billion facility being built in Dubai that will eventually be able to power 120,000 homes.

However, this technology is somehow questioned in some countries. Some arguments have been presented for and against W2E technology. The potential impact on Climate Change is a key issue in modern waste management and it is crucial to understand the role of this technology with respect to CO2 emissions and its benefits.

Emissions are indeed the aspect of this technology that gathers more attention for obvious reasons. Here are a couple of aspects that should be taken into account:

- This is a sector with many years of experience in the most developed countries and consolidated actors. Technologies have improved massively over the last 30 years and current plants have nothing in common with those that were built in the 80s. Strict emission controls are implemented, with continuous measurement systems that are accessible for everyone.

- The limits on W2E emissions are currently very low when compared to other industries, and the regulations keep pushing for those limits down. In ACCIONA for instance, we are already designing our plants keeping in mind the strictest regulations that we envision will come like the new Best Available Techniques (BAT) reference document. BAT is led by the European Commission's Joint Research Centre and is still currently under discussion. We strive to be at least one-step ahead on this matter. We focus in Methane capture because it is far more devastating to the climate because of how effectively it absorbs heat.

- Last but not least, W2E plants are just part of the solution for waste. W2E plants do have emissions to air, and despite being low, or very low if compared to landfills, they are still emissions. The hierarchy of residues is simple and strong at the same time: we should be focusing on reducing and recycling our waste first. Of course, with today´s technologies, there is always going to be a very significant part of our waste that cannot be recycled, and that´s where we have to use W2E to avoid the landfill.

There are also some concerns on the residues produced by this W2E process like the Bottom Ash and the Air Pollution Residues (APCRs), generated both by this technologies. The Bottom Ash is the incombustible part of the incinerated waste. In 2017, around 96 million tonnes of waste were treated in W2E plants in Europe, which led to the production of approximately 19 million tonnes of Bottom Ash. However, important quantities of metals and minerals are present in these residues that offer many opportunities for recycling.

In our latest projects in the UK and Australia, we are achieving very high (95% or even 100%) diversion rates. This means the percentage of waste that does not end up in a landfill. Bottom Ash can be maturated and treated to remove metals in order to use it as an aggregate material in construction. APCRs are more complex, because they contain all those contaminants present in our waste that we have captured to avoid them having an adverse in the environment. These represent around 4% of the incoming waste. With today´s technology, we can chemically neutralize them and ensure that they do not have a negative impact on our environment. Of course, that has a cost, but here is where we need to be all aligned in a very clear message: not doing things in the right/sustainable way has also a cost, on our planet and the generations to come. A cost that may not be so immediate, but that we cannot ignore anymore.

These projects may have some public opposition as people is not fully aware or well informed on how much the technology has evolved when compared to old plants in the 80s. In any case, what I feel is more important is to properly explain which is the role of W2E Plants and how they are avoiding toxic waste, reducing the footprint of landfills and the bad smell and environmental hazard associated with landfills. I think we all (private and public entities) should put our efforts to better explain how necessary is to manage our residues in a better way. We need to have our minds open for new solutions, which I´m sure will keep on coming. Our responsibility is to do things the best way we can do, and today that certainly involves reducing 8or finally removing) the use of landfill.

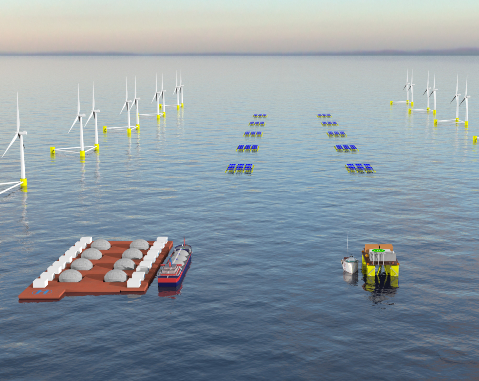

Looking into the future, the W2E plants efficiency is another area for continuous improvement in this technology. New materials are being used to increase the steam parameters and achieve higher efficiencies. In ACCIONA, we are particularly interested in those projects that combine the energy production with the use of the heat in district heating schemes. This combination may massively increase the efficiencies. Our technical teams are also looking at potential solutions that we hope may help to optimize the value recovered from our residues such as the hybridization with other technologies.

Renewable energies is one of our main priorities, but sustainability is a broader concept and probably here in this context makes more sense. Being sustainable is not only obtaining renewable energy –which for sure matters- but also providing environmentally sound solutions to the problems we have. This target is embodied in the 17 Sustainability Development Goals (SDGs) issued by the United Nations (UN) that ACCIONA is constantly following. It is necessary to inform society about the need to give adequate treatment to our solid waste. This can certainly can go along with our responsibility towards preserving the environment. More and more, landfilling our residues is not aligned with the SGDs.

View ACCIONA Social Networks